The CHIPS Act, signed into law in August 2022, stands for Creating Helpful Incentives to Produce Semiconductors for America Act, is a piece of legislation aimed at boosting semiconductor manufacturing and research in the United States. The Act invests nearly $250 billion over five years — one of the largest five-year federal research and development investments in U.S. history. Globally, the world is looking at the United States and is envious of what we are doing on the CHIPS Act—it’s a big and positive first step. And we also have to do more.

Briefly, the CHIPS Act moved relatively quickly through the legislative funnel; it may have seemed slow in business terms but it was fast in government terms. It’s not unusual for a business to do something in five weeks, while the government will take five years. The fact is that this was done in roughly eighteen months. Approximately a year and a half after getting approved, they started to deliver funds, and for our government, that is pretty fast! Although, I will add that the United States should have accomplished this sooner.

The CHIPS Act was put on the legislation radar almost two years before it got approved, fairly quickly. It had bipartisan support, but it still took that long to get through the entire signing-into-law process. There was some complex legislation, political considerations, and prioritization issues that did not make the path an easy one. Now that it is signed, the plan is for the CHIPS Act to use most of its dollars to build silicon, and this is important for many reasons.

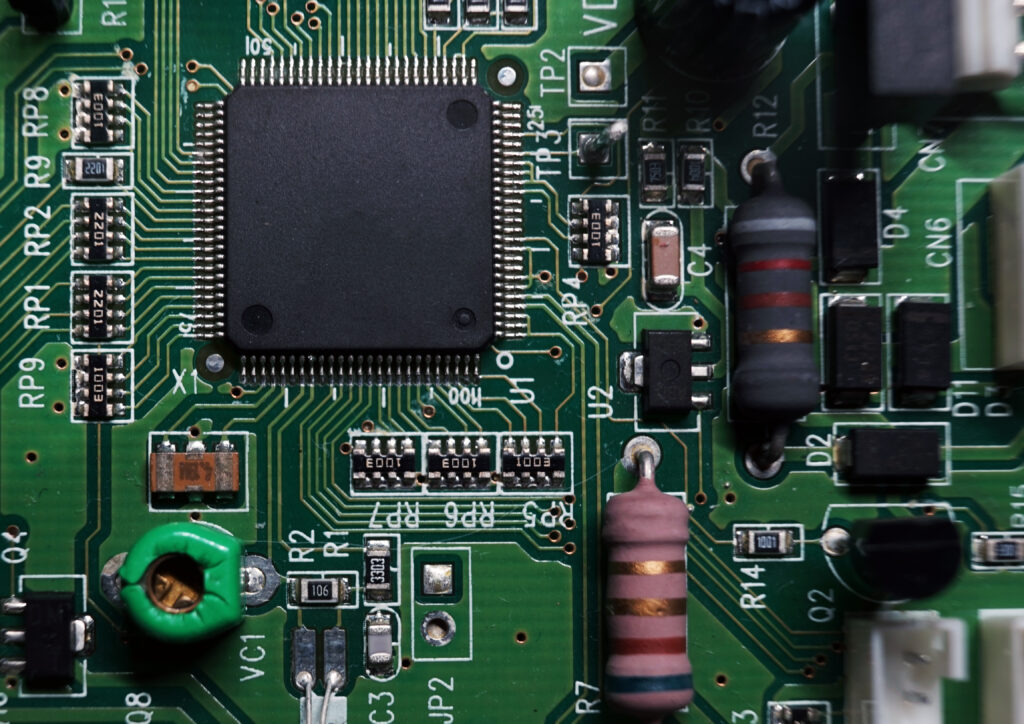

We are trying to recreate the ability to actually manufacture the latest semiconductor technology that exists in the world, and that’s a good thing. The challenge is surface level, and the CHIPS Act came about because of the shortage. During the global pandemic, we didn’t have the chips we needed. Many cars sat on their respective lots because they were missing microprocessors. That’s when we realized more urgently that we needed to solve this disparity. Building silicon for semiconductor manufacturing is crucial. They form the foundation of modern technology by powering electronic devices such as smartphones, computers, medical devices, refrigerators, and automotive systems. How can a country like United States not have manufacturing on our own shores in place? Furthermore, we will need an industrial base that can support our needs.

According to U.S. Senate Committee on Commerce, Science, and Transportation, “The law supports our men and women in uniform by helping ensure that more of the semiconductors used in U.S. military systems are made here at home. Right now, 90 percent of the most advanced semiconductors are made in Taiwan alone. More reliable access to advanced semiconductors ensures that our military has the firepower to deter enemies and keep us safe.”[1]

To build the workforce of tomorrow, it is necessary that we have our own systems for making semiconductors.

Beyond creating chips in country, there are other critical aspects of the electronics ecosystem that cannot be ignored. Without investments in those key areas, even with chips locally created, the systems needed cannot be made. While the CHIPS Act is a good start, it is only that … even for the semiconductors … just a start. It is imperative that we think of silicon, but also of how to take silicon to systems. A pile of semiconductors can’t do anything without supporting hardware.

We are not going to bring back every single aspect of the entire ecosystem to the United States so that we could build every device, every piece of clothing, whatever we want—that is simply not feasible. The problem is when we have tensions between countries and those tensions get out of hand. This is an effort not just by the United States but by the European Union and India. They all have their over version of the CHIPS Acts that they are working on because they recognize the power of silicon. And the pandemic helped just rub everybody’s noses in the fact that you cannot do anything without semiconductors.

Unfortunately, what we do not seem to be talking about is that even if we build these, we do not have people that can make them.

This leads to a new problem in that there is a workforce component to almost every part of these acts, wherein we are trying to figure out the best way to train people to give them new jobs in this arena. Again, this is all very positive. I had the opportunity in February to attend a meeting in the White House discussing how to develop the right workforce utilizing CHIPS Act funds. We can hopefully develop not just engineers, but technicians as well, which will allow many people to have roles in this new electronics economy.

Building silicon helps maintain competitiveness in the global market, and it is essential for driving the innovation behind that. It will ensure national security and create jobs in our increasingly technology-driven world. We have got to further promote these both, along with the economic growth the broader electronics industry can bring. Silicon-to-systems thinking is what is required.

[1] https://www.commerce.senate.gov/2023/1/1.